The Problem

Traditionally, expert tailors take customer measurements, produce garments in-house, and supervise the cutting of garments. In contrast, ‘modern tailors’ outsource the production of garments to expert tailors based overseas after obtaining customer measurements. Currently, modern tailors use three methods to obtain body measurements:

The third option has become increasingly popular. After carefully studying the process of various tailors, we realised that training sales staff to take measurements could be made more accurate and yield higher cost-savings. We operationalised ‘accurate’ as ‘measuring within 5% of an expert tailor’s measurement’ and ‘cost-saving’ as ‘taking up less monetary resources and time compared to current methods’.

What we did

Design statement: Build a guidance system for modern tailors to enable their salespersons to take accurate body measurements at high cost-savings.

We designed a solution that uses a guidance system to train salespersons in modern tailor stores empowering them to replicate the mastery and the finesse of their master tailor. With the use of a smart tape, an interactive guidance system and our proposed pose estimation algorithm, we were not only able to obtain curved and linear measurements of users with an accuracy of +/- 5mm but also achieve time and cost savings.

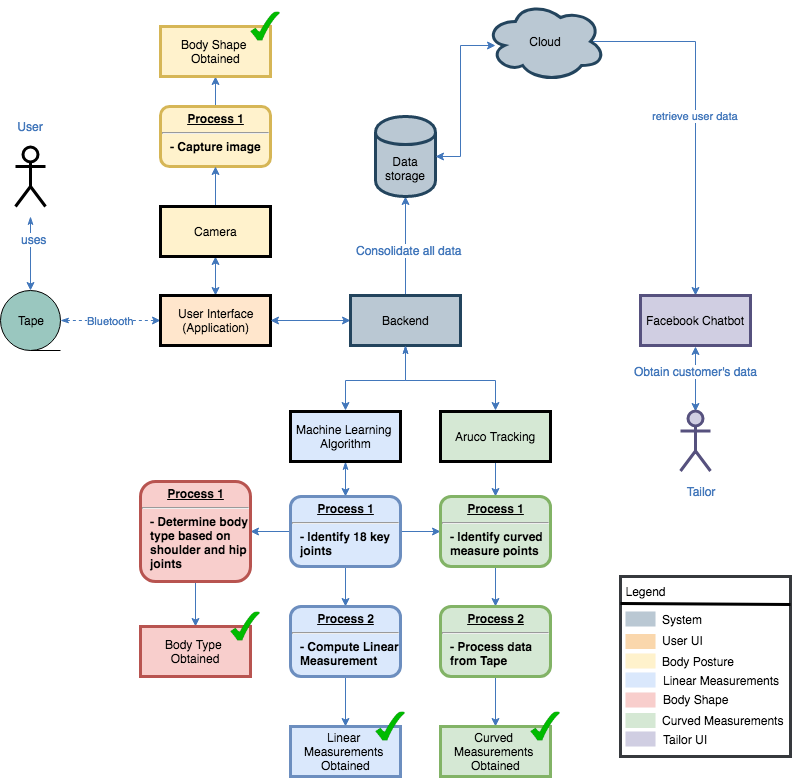

The figure below shows a detailed breakdown of the different components within the UNIT smart sensing platform:

How it works

Our system is made up of two sub-systems: (1) a smart digital measuring tape that we designed from scratch, and (2) a smart system with real-time feedback. The smart system constantly tracks the smart tape to guide a salesperson step-by-step in obtaining accurate body measurements from a customer.

Watch a full demonstration in the following video:

A detailed report of the project can be found here.

The code can be found on GitHub here.